The Gentle Conveyor Bud Sorting Machine is a custom-built solution designed for cannabis producers who prioritize flower integrity, trichome preservation, and visual quality.

Unlike vibration-based or tumbler-style sorters that can damage buds, this machine uses a smooth conveyor system to gently move flower through gradually widening sorting gaps, reducing trichome loss, bruising, and stem breakage. It can sort buds from as small as 3 mm up to 25 mm or more, making it ideal for premium indoor or greenhouse flower operations. Equipped with a variable-speed motor, it allows precise control based on product density and moisture. The adjustable grading mechanism ensures smooth separation without harsh impacts.

Built with 304 stainless steel and food-grade silicone, it meets sanitation standards while minimizing surface abrasiveness. Despite its industrial durability, the machine is compact enough to fit through standard doors and features locking casters for easy repositioning.

Compared to other systems, it offers gentle handling like high-end conveyor sorters but at a much lower cost, making it perfect for operations upgrading from hand sorting without compromising flower quality.

Gentle Conveyor Bud Sorting Machine

Precision Size Grading with Minimal Flower Damage

This custom-built gentle conveyor bud sorting machine was designed specifically for producers who prioritize flower integrity, trichome preservation, and visual quality over brute-force throughput.

Unlike tumbling or vibration-based sorting systems that aggressively roll, drop, or abrade flower, this machine uses a smooth, controlled conveyor-style movement that carefully advances buds through progressively sized sorting gaps. The result is consistent size grading with dramatically reduced handling stress.

Key Advantages

• Ultra-Gentle Sorting Action. No tumbling drums. No vibration plates. No aggressive agitation. Flower is carried and guided using a soft, controlled conveyor system that minimizes trichome loss, bruising, and stem snap.

• Wide Sorting Range

• Sorts flower as small as ~3 mm

• Upper discharge accommodates buds up to ~25 mm, approximately the diameter of a U.S. quarter

• Larger flowers exit cleanly at the rear without being forced or compressed

• Variable Speed Control Equipped with a variable-speed DC motor, allowing operators to fine-tune feed rate based on flower density, moisture content, and desired gentleness. This provides far more control than fixed-speed or vibration-based machines .

• Adjustable Grading Mechanism Sorting gaps gradually change along the conveyor length, enabling smooth separation into multiple size classes without sudden drops or impacts. Minor size adjustments can be made quickly via the built-in adjustment system.

Materials & Build Quality

• Frame & Structural Components:

• 304 stainless steel

• Corrosion-resistant and easy to clean

• Product Contact Surfaces:

• Food-grade silica gel (silicone)

• 304 stainless steel

This combination delivers the same food-safety standards as all-stainless machines while significantly reducing cost and surface abrasiveness.

Many competing machines rely on excessive stainless steel mass or rigid metal tumbling surfaces. This design intentionally uses food-grade silicone where appropriate to protect delicate flower structure without compromising sanitation.

Dimensions & Weight

• Length: 210 cm → 82.7 inches (6.9 ft)

• Width: 80 cm → 31.5 inches

• Height: 80 cm → 31.5 inches

• Weight: 140 kg → ~309 lb

Despite its solid industrial build, the machine is designed to fit through standard door openings lengthwise. Locking casters allow for repositioning within a processing space once installed.

Ideal Use Cases

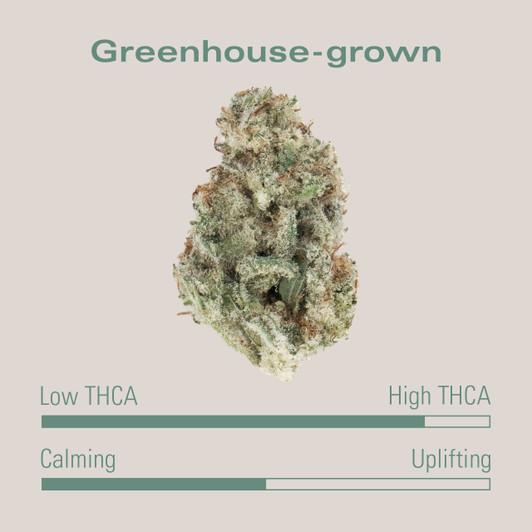

• Premium indoor or greenhouse flower

• Operations focused on bag appeal and terpene retention

• Producers transitioning from hand sorting to scalable automation without sacrificing quality or spending outrageous amounts of money.

Comparison to Common Alternatives

• Versus Tumbler-Style Sorters (e.g., Centurion):

• No rotating drums

• No repetitive dropping or rolling

• Significantly less flower degradation

• Avoids paying ~$10,000 for technology that actively reduces quality

• Versus Vibration-Based Sorters:

• No harsh shaking or rapid oscillation

• Better suited for premium flower and hand-trimmed product

• More consistent size separation without mechanical stress

• Versus High-Cost Conveyor Systems:

• Similar gentle conveyor principle

• Comparable results without excessive stainless steel markup

• Substantially lower total cost while maintaining food-grade standards