Indoor Cultivation: Our Journey to Growing High-Quality Hemp Flower

28th Jun 2022

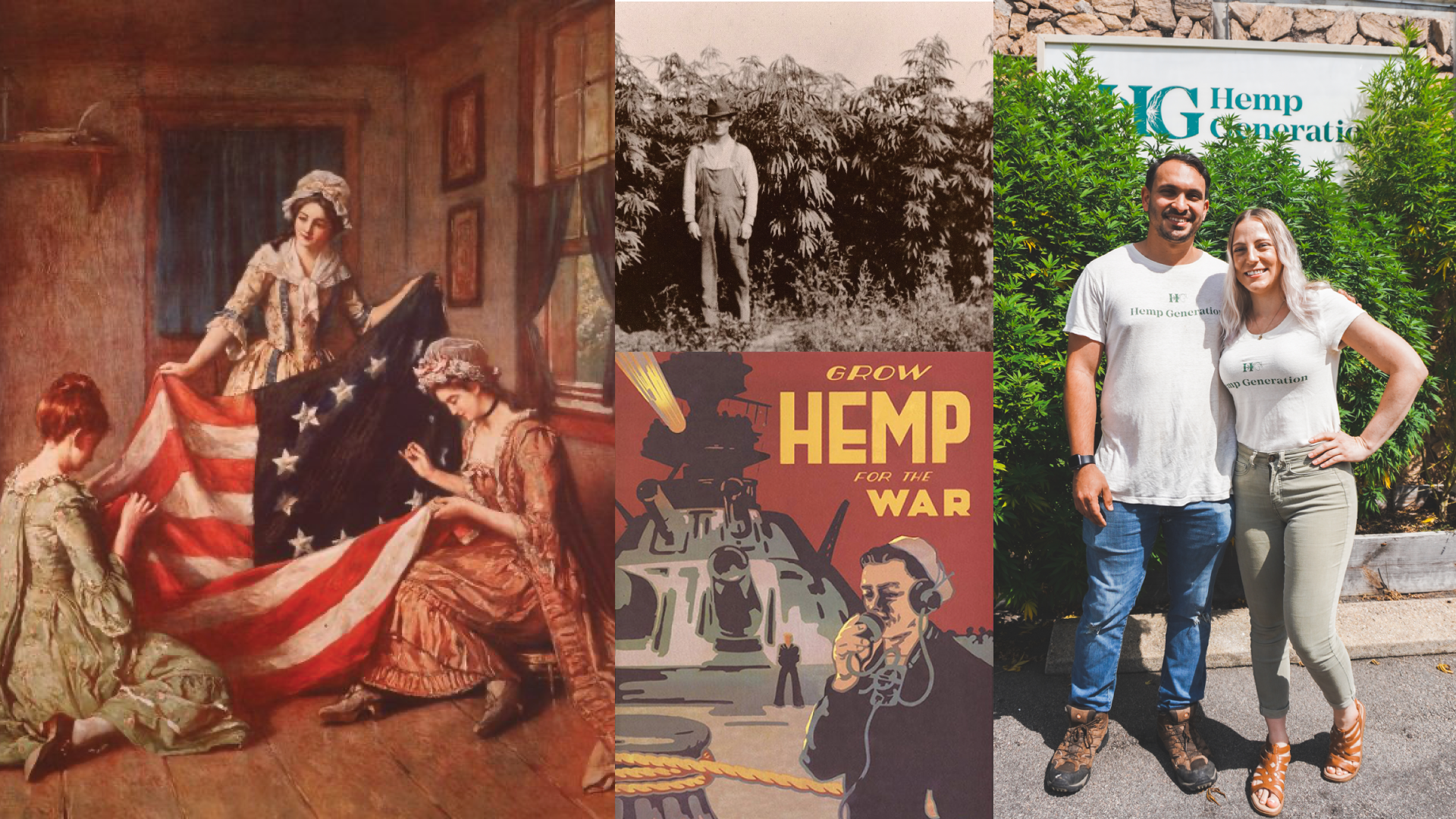

Our journey

When we started growing hemp outdoors in 2018, hundreds of farmers emerged to do the same. The goal for many was to grow as much hemp as possible, sell it, and make profit. From 2018 to 2019, the number of licensed acres in the U.S. quadrupled, according to the Hemp Industry Daily. Fast forward a couple years and many of these farmers, companies, and brands are either no longer in operation or scaled down. Farmers began planting less hemp due to regulatory uncertainty, a surplus of hemp flower and biomass, and continuously falling wholesale prices, which also lead to thousands of CBD brands being wiped out. Despite the decrease in production and emerging brands, in 2020, the CBD industry brought in $4.7 billion in the U.S. alone and is expected to grow up to $16 billion by 2025, according to the Brightfield Group. The hemp industry was such a new and pioneering space that it was difficult for consumers to catch up and meet the oversupply of hemp flower, yet many brands still managed to standout and continue thriving. We believe that one of the major factors that played a role in the success of these brands was the quality and representation of their products.

After our experience with growing flower, wholesaling to retailers, and observing the exploding hemp market around us over the past few years, we realized that there was something important missing. Very few farmers and brands genuinely made the effort to cultivate clean, accurately represented, and high-quality smokable flower. Finding consistent and high-quality flower across the state proved to be difficult. With so many brands flooding the shelfs it was hard to distinguish which ones are trustworthy, good quality, and safe. The truth is that growing high-quality hemp flower is very difficult, time consuming, and costly. Our first outdoor grow proved to be very challenging to produce flower that could meet our standards. The following 2 years we grew in 2,000 sqft greenhouses. Here we were able to control more factors like soil, lighting, and environmental exposure, while keeping costs at a sustainable level. Through this experience we produced some of our best and most loved CBD flower. The challenges and obstacles that we've overcome over the past few years have made us better growers and have taught us a lot.

With the consumer's long-term wellness in mind, in 2021, we continue to embark on our mission to grow the best quality flower we possibly can.

Why grow indoor hemp?

In order to uphold our mission of providing consistent, fresh, high-quality flower, we needed to upgrade our growing practices. We decided that an indoor grow would allow us to provide new genetic strains at a higher turn-over rate, work with fresh harvests all year around, and enhance the quality so that we are not completely dependent on Mother Nature. Unlike outdoor or greenhouse grows, an indoor grow is a fully-enclosed space untouched by uncontrollable variables like weather, temperature, humidity, and pests. We believe that in order to produce the best quality products, it’s important to control as many factors as we can within the grow. We now have full control over the growing medium, environment, and lighting to ensure pristine cannabinoid-rich flowers.

Key Components for a Successful Indoor Grow

There are many necessary factors when it comes to sustainably growing cannabis in an indoor facility. An indoor grow provides maximum controllability which means each and every aspect needs to be fine-tuned for maximum quality and yield. There are many sources to growing great cannabis indoors and this article is just one. Another great book that helped us gain knowledge on growing techniques is the Marijuana Grow Bible by George Cervantes.

Our Indoor Grow Design

Because cannabis plants highly depend on their environment to produce quality flower, we kept a few things in mind when coming up with the best design for our indoor grow. Efficient layout, visual appeal, and extreme precision were our top priorities in order to grow the highest quality flower.

Our grow is located at our retail location Hemp Generation Wellness in Cary, NC. We have two enclosed rooms: one is the flowering room about 150 sq. ft and one is the vegetative room and is about 50 sq.ft. Call us to schedule a tour of our growing room!

Room size and Spacing

Cannabis grow spaces can range from small grow tents to large industrial facilities. The main factors that should be always be considered when planning an indoor grow are: the number of plants, calculating space for utilities like AC systems, humidifiers (and/or dehumidifiers), and space. Pruning, inspection, pest control, and harvesting are also key points to take into account for later in your operation. All these factors will look different for each and every grow. Grow rooms must be very thought-out and meticulously planned in order to maximize efficiency.

Lighting

Cannabis needs proper lighting in order to ensure rapid growth. This lighting is highly dependent on the proper spectrum and intensity. For example, the sun is more intense in summer months than winter months. Cannabis flowering is dependent on the photoperiod (the amount of uninterrupted lighting and darkness typically in a 24 hour period), also called the light cycle. For vegetative growing states, most cannabis plants need 18-24 hours of light; the remaining time would be dark with no interruption with the possible exception of moonlight. For the flowering state of growth, 12 hours of light and 12 hours of uninterrupted darkness will prompt the plant to think that winter is coming so that it is time to produce seeds. Lighting is so crucial in plant growth, size, flowering and overall health. If a plant is not receiving the correct amount of light during the various stages of growth, it will not thrive or produce good yields. If the light cycle is really thrown off, the plant may become a hermaphrodite or form odd growths like curling leaves. (possibly insert pictures of this kind of growth?).

It is always best to take inspiration from Mother Nature to help grow the plant to its maximum potential. In our grow we are using 6 Fohse 1000W lights for our flowering room and 2 600W fixtures for our vegetative room.

Temperature and humidity

The correct temperature and humidity is key to having a successful grow regardless of grow type or location. Without precise control of these two variables, there is risk for complication. Too much humidity can cause disease, molding, slow growth, and root rot. Too little humidity or too high of a temperature can cause heat stress, slow growth and promote an environment for mites. There are different ideal temperature and humidity ranges depending on the stage of the plant. The best temperatures for cannabis in vegetative states range from 68*F to 77*F. Temperatures should also be dropped about 4-5*F during dark hours. Humidity should remain around 70% or more for vegetative plants unless there is a presence of disease. When plants are flowering, they will need much lower humidity to prevent disease. Ideal day temperatures are 69*F to 71*F with night temperatures being at least 5*F less at night. In the later stages of flowering, the nights will grow even colder. Humidity should remain around 50% and should not have much fluctuation. As previously mentioned, everyone has their preferred methods: these are just the general guidelines.

In our grow, we will be using a wall mount mini split AC system to help prevent the escape of any CO2 we release and a large dehumidifier to ensure we can keep the space at the desired humidity level. We control our environment with Trolmaster’s Humidity Station and Temperature Station.

CO2

Cannabis plants convert CO2 through photosynthesis into energy in order to grow. To obtain increased yields and stronger plants, supplemental CO2 will be needed in order to grow efficiently. CO2 can be slowly increased as the plants grow ranging from 400 to 2,000 ppm. CO2 outdoors is around the 300-400ppm range and in tight offices with many people, CO2 levels can get to 1000ppm or possibly more. Typically growers will slowly increase the amount of CO2 their plants receive to reduce shock and most experienced growers find 1200ppm to be a sweet spot.

For our indoor grow we will be supplementing our vegetative plants with around 700-800ppm and in the flowering stage we set our levels to 1420ppm. During the night hours we do not sustain CO2 levels since the plant is not photosynthesizing. We evenly distribute the CO2 for our grow room using a CO2 rain system (https://amzn.to/3mLFCon) and a CO2 regulator (https://amzn.to/3kBVvv1) which comes with a rubber tube that goes to the rain system and sits on the CO2 tank. This allows us to control the flow rate of CO2. The valve that opens and closes the line is controlled with the Trolmaster Hydro-X and the CO2 Device Station.

Trellis

Incorporating trellis netting to support the blooming plant is another way to maximize the yield for your grow space. There are many different ways to trellis plants. Plastic netting, unlike fibrous netting, is one of the most popular and carries the advantage of resisting the growth of mold. During the last few weeks of flowering, plants will become very heavy and will need support. The trellis not only holds the plants up when they get heavy, it also allows the plant to rest on the netting throughout the grow process to preserve energy and use that saved energy for growing larger flowers. It is said you can get 20-30% increased yields if the plant is given the extra support it needs.

We are excited to announce that we are collaborating with the Ganjagrid Plant Vibration Trellis System from our friend Glenn Holland. We are seeing if the use of this device can help stimulate the plant through the vibrations of sound. Our intent is to do a side-by-side comparison test on one of our grow tables to gather more data on the effects of vibration and music stimulation. We are currently playing them Mother Earth’s Plantasia by Mort Garson made in 1978. It is possible that these vibrations may increase production of cannabinoids, decrease internodal spacing, and/or hasten flowering speed.

Irrigation

Plants need to be watered on a consistent schedule, and the watering system needs to be reliable and consistent. There are many different methods to designing this system depending on your set up, grow environment, grow medium, and type of nutrients. A lot of the time these systems will consist of a spaghetti drip system inserted in the pots from the main plastic tubing that goes back to the water tank or nutrient delivery system.

Our irrigation system will be primarily composed of a water tank to store fresh tap water with an automatic refill system to keep water in stock. Then I have an air pump and an air stone to oxygenate the water before passing it through our nutrient delivery system series of Dosatrons then we test it with in line Ph and Ec probes to ensure our plants are getting exactly what’s prescribed.

Nutrients and Compost Tea

There are a variety of types of nutrients and nutrient combinations that can be used in a cannabis grow. In general, plants need four primary nutrients (nitrogen, phosphorus, potassium, and magnesium). These are the building blocks to any type of cannabis fertilizer. There are chemical nutrients, organic nutrients, mineral salts, and many other combinations. Nutrient formulas will need to be varied depending on the stage of plant growth.

For our grow we do a combination of mineral salts and compost tea formulations to deliver on everything the plant needs. Here is where we dose silica, our custom cannabis A & B formula ( contact us to purchase or for more details) specifically formulated to give the plant everything it needs to properly grow. Calcium and magnesium is already balanced for plants to grow without any signs of deficiencies. At the end of every grow cycle however, we flush our plants with reverse osmosis water to drain any remaining salts out of the growing medium. We use coco-coir with a small amount of perlite and vermicompost (0.1-15% by volume).

We also administer compost tea weekly. All our knowledge of compost tea is based on one consistent recipe. We follow all the instructions to make active aerated compost tea Microbe Organics when it comes to organic fertilization.

Our Vision

Our vision for the future of our grow operation includes doing some genetic selection trials and continuing research with vibrating plants along with playing them music. By doing genetic selection we can stumble across novel varieties that can be grown again at the customers demand.